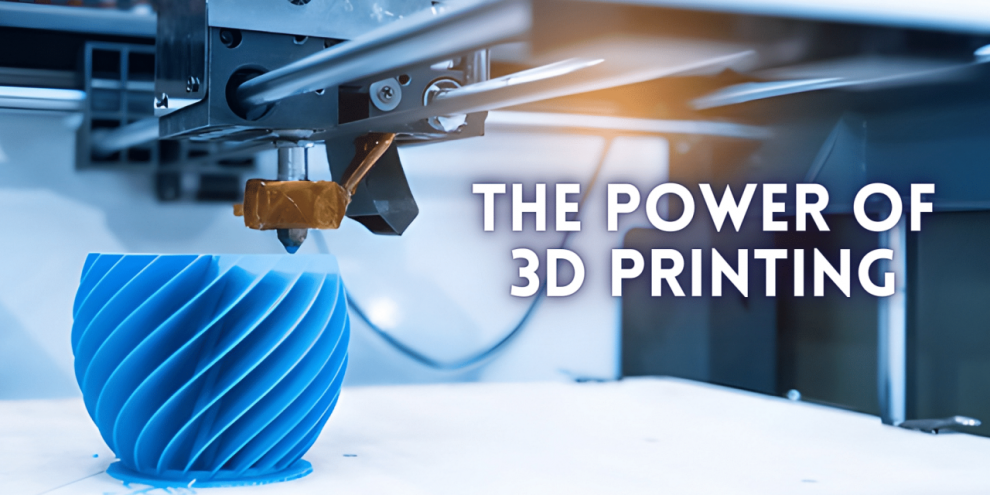

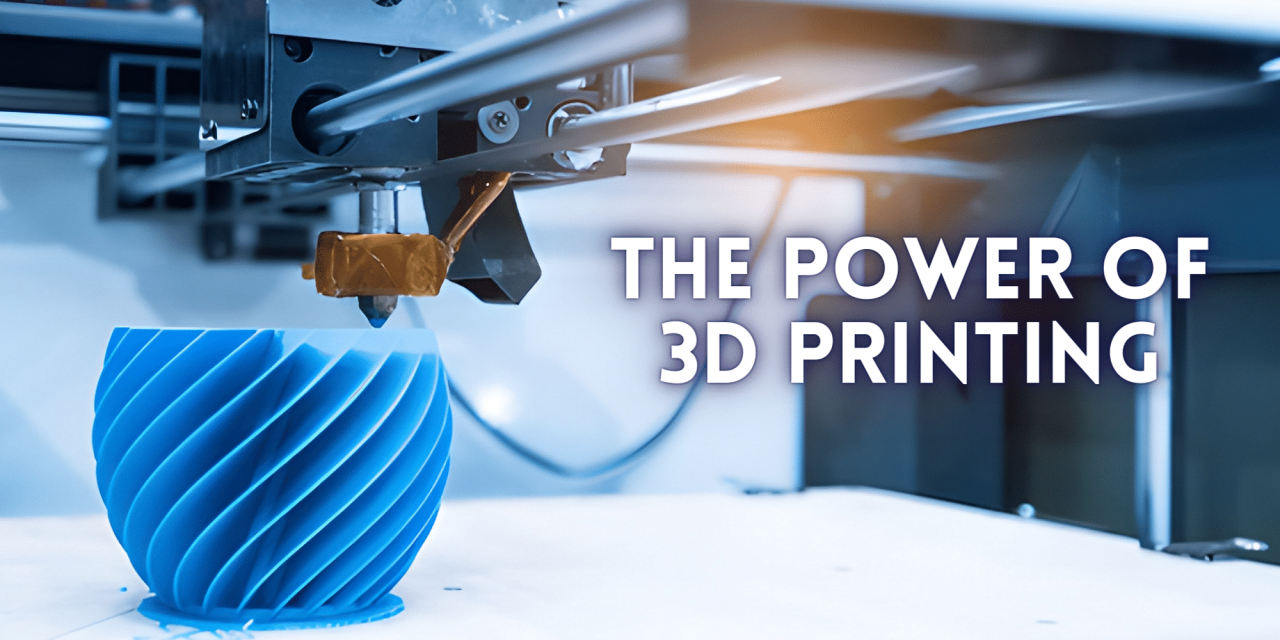

Avi Reichental, a leading thinker in 3D printing technology, once said, “3D printing is going to be a game changer. Not only does it provide you with the opportunity to do something really cool, it also could completely change the way that we think about manufacturing.” Let’s delve into how 3D printing is shaping a new era in manufacturing and how its broad-ranging implications are affecting various industries.

The Science Behind 3D Printing

3D printing, or additive manufacturing, is a technology that constructs three-dimensional objects from a digital model. Unlike traditional manufacturing, which often involves cutting away excess materials, 3D printing builds objects layer by layer, drastically reducing waste.

The process begins with a digital design created in a CAD (Computer-Aided Design) program or a 3D object scanner. The 3D printer then reads this digital file and lays down successive layers of material – such as plastic, metal, ceramic, or even biological matter – until the object is complete.

Revolutionizing the Manufacturing Industry

3D printing is disrupting traditional manufacturing in several significant ways.

Firstly, it allows for rapid prototyping. With 3D printing, manufacturers can design, create, test, and refine a product in a fraction of the time it would take using traditional methods. Ford Motor Company, for example, uses 3D printing to create prototypes of many vehicle parts, speeding up the design process and getting products to market faster.

Secondly, 3D printing enables mass customization. Unlike mass production, which creates many identical items, 3D printing can create custom objects without additional cost or time. For instance, Align Technology uses 3D printing to make individualized Invisalign teeth aligners for millions of customers.

Finally, 3D printing significantly reduces waste. Traditional manufacturing methods, like machining and casting, often discard large amounts of material. In contrast, 3D printing uses only the exact amount of material required, contributing to a more sustainable manufacturing process.

Applications in Various Industries

3D printing is not limited to the manufacturing industry; its implications span across multiple sectors.

In healthcare, 3D printing is being used to produce customized prosthetics, implants, and even bioprinted organs. A company called Open Bionics, for example, is using 3D printing to produce affordable, customizable prosthetic limbs.

In aerospace and defense, companies like SpaceX are using 3D printing to create intricate parts that are lighter and stronger than traditionally manufactured components. The use of 3D printing significantly reduces the production cost and time of these parts.

In architecture and construction, 3D printing is used to create detailed models, components, and even entire buildings. The company Apis Cor, for instance, 3D printed a house in just 24 hours.

In food production, 3D printing is used to create customized food items. Foodini, a 3D food printer, allows chefs to create intricate designs and novel food structures.

The Future of 3D Printing

As 3D printing technology continues to evolve, we can anticipate its further integration into our everyday lives. There will be more 3D printed products, from clothes to cars and even houses. In the words of entrepreneur Peter Diamandis, “3D printing is a revolution: just not the revolution you think. Yes, the ability to ‘print’ or rather build any object at home is amazing. But it’s the behind-the-scenes revolution that is going to change everything.” With its wide-ranging implications and its potential to revolutionize manufacturing as we know it, 3D printing indeed signifies the dawn of a new era.